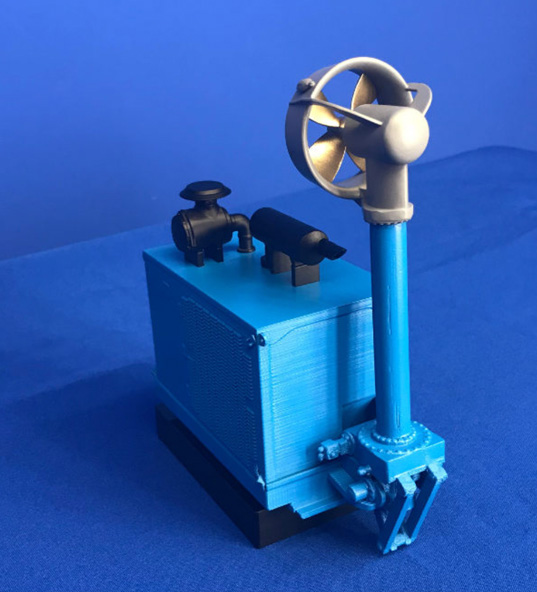

3D printing service at HTS Model Making provides designers and engineers with custom prototypes and functional, end-use parts within days. Our expertise in materials and machines will guide your design concept from file to 3D printed part. These are some of the available 3D printing technologies:

-

Fused Deposition Modeling (FDM)

-

Color-Jet-Printing (CJP)

-

Stereolithography (SL)

-

Laser Sintering (LS) or (SLS)

-

Direct Metal Laser Sintering

Fused Deposition Modeling (FDM)

FDM printing uses a plastic mono-filament that extrudes layer by layer to produce an exact 3D printed part. These are thermal plastics that fuse each layer by using extreme heat. FDM parts are strong and durable; they can be light-weight and are an excellent choice for functional prototyping.

Material Choices |

Uses |

|---|---|

| ABS | Available Colors: Ivory, White, Black, Dark Grey, Red, Blue, Olive Green, Nectarine, & Florescent Yellow. Ideal for affordable design concepts and quick studies. |

| Nylon 12 | Nylon 12 offers excellent chemical resistance and is perfect for friction surfaces. Highly recommended for extreme performance in parts with thin wall surface features. |

| Polycarbonate | Ideal for functional parts and has superior strength. |

| Ultem | Ultem is a high-temperature, chemical-resistant thermoplastic, perfect for design testing in extreme conditions. Ideal for autoclaving and food-safe applications. |

Color-Jet Printing (CJP)

Color-Jet Printing (CJP) incorporates advanced 3-channel CMY full-color with a low-cost composite powder for 3D printed parts. As each layer of the part is formed, the powder is colored, hardened, and encased in unused powder. This 3D printing service eliminates the need for support structures and allows for complex geometries. Though this technology is not suitable for form fit, snap, or rugged prototypes, it is excellent for product design studies and texture-mapped, scanned data such as people, pets, and buildings.

Material Choices:

VisiJet PXL

Stereolithography (SL)

Stereolithography (often called SLA or SL) rapidly builds components using a precise UV laser to cure and solidify thin layers of a photo-reactive resin. One of the most accurate 3D printing technologies, SL is ideal for concept models, form and fit studies, and investment casting patterns.

Stereolithography is not generally considered suitable for production applications because the photo-reactive resins used in the process do not remain stable under long exposure to UV light. However, SL is often used to make precise investment casting patterns to create end-use metal parts.

Material Choices |

Uses |

|---|---|

| Somos WaterShed | ABS-like performance with the clearest quality. Good for flow analysis and prototype design. Resistant to water and humidity. |

| Somos NeXt | Tough SL resin that is ideal for low-volume manufacturing and functional prototypes. Somos NeXt offers improved moisture resistance and greater thermal properties. |

Laser Sintering (LS) or (SLS)

Laser Sintering (LS) or Selective Laser Sintering (SLS) is a process in which a CO2 laser draws onto a hot bed of thermoplastic powder, where it lightly sinters (fuses) the powder into a solid.

An advantage of LS is that, as a part is made, it remains encased in powder. This 3D printing service eliminates the need for support structures and allows for complex geometries. LS uses a nylon-based powder similar to actual engineering thermoplastics, so parts exhibit greater toughness and are heat resistant. LS offers a large build volume, but it lacks ultra-fine details due to its rough surface.

Material Choices |

Uses |

|---|---|

| Nylon 12 AF | Aluminum-filled nylon produces strong, stiff parts with a grey metallic appearance. Excellent for functional prototypes, jigs, and fixtures. |

| Nylon 12 GF | glass-filled nylon material with excellent mechanical stiffness. Nylon 12 GF offers elevated temperature resistance while staying dimensionally stable. Excellent for housings and enclosures, and functional prototypes. |

Direct Metal Laser Sintering

Direct Metal Laser Sintering (DMLS) uses a precise, high-wattage laser to micro-weld powdered metals and alloys such as Inconel, Aluminum, Stainless Steel, and Titanium. 3D printed parts will have a surface finish comparable to investment casting. By offering our post finishing services, printed parts can be de-burred, bead blast, or polished and ready for real world applications.

DMLS parts are strong, durable, and heat-resistant. DMLS eliminates time-consuming tooling, and creates complex geometries not possible with other metal manufacturing processes. DMLS produces functional metal parts with the same speed as other 3D printing services that only produce plastic parts.

Material Choices:

Stainless Steel

Aluminum

Inconel

Titanium

We are proud of the detailed 3D models we’ve created and the excellent reputation we’ve developed with our customers.