What are HTS’s Additional Modeling Services?

HTS’s Additional Services include all aspects of 3D Model maintenance even if we didn’t create it. If your 3D model needs repair, restoration or a thorough cleaning contact us. We are here to help. We are also available to move / setup your 3D model. Other Services are:

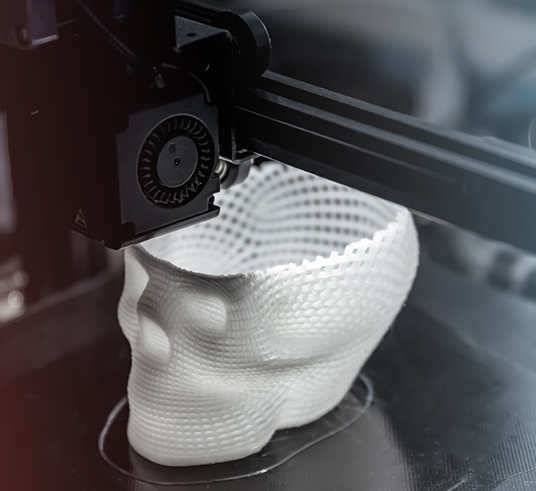

3D Printing

HTS can print a physical object from a digital design. Creating a 3D model of your logo is a very simple example.

CAD Services

HTS has the knowledge and skill to create 3D CAD files for all professions.

We recently created the CAD file for an Endoscope Probe which required extreme accuracy.

Laser Cutting

HTS offers laser cutting services for a variety of materials as listed below. Don’t hesitate to contact us about a material not listed.

Rapid Prototyping

3D printed prototypes are cost-effective – let HTS turn your ideas into realistic proofs of concept. We can produce your test part very quickly.

3D Printing

3D printing service at HTS Model Making provides designers and engineers with custom prototypes and functional, end-use parts within days. Our expertise in materials and machines will guide your design concept from file to 3D printed part.

HTS Advanced Solutions supports the following 3D printing technologies:

Color-Jet Printing (CJP)

Color-Jet Printing (CJP) incorporates advanced 3-channel CMY full-color with a low-cost composite powder for 3D printed parts. As each layer of the part is formed, the powder is colored, hardened, and encased in unused powder. This 3D printing service eliminates the need for support structures and allows for complex geometries. Though this technology is not suitable for form fit, snap, or rugged prototypes, it is excellent for product design studies and texture-mapped, scanned data such as people, pets, and buildings.

Material Choices:

- VisiJet PXL

Laser Sintering (LS) or (SLS)

Laser Sintering (LS) or Selective Laser Sintering (SLS) is a process in which a CO2 laser draws onto a hot bed of thermoplastic powder, where it lightly sinters (fuses) the powder into a solid.

An advantage of LS is that, as a part is made, it remains encased in powder. This 3D printing service eliminates the need for support structures and allows for complex geometries. LS uses a nylon-based powder similar to actual engineering thermoplastics, so parts exhibit greater toughness and are heat resistant. LS offers a large build volume, but it lacks ultra-fine details due to its rough surface.

Material Choices:

Nylon 12 AF:

- glass-filled nylon material with excellent mechanical stiffness.Nylon 12 GF offers elevated temperature resistance while staying dimensionally stable.

- Excellent for functional prototypes, jigs, and fixtures

Nylon 12 GF:

- Aluminum-filled nylon produces strong, stiff parts with a grey metallic appearance

- Excellent for functional prototypes, jigs, and fixtures

Direct Metal Laser Sintering

Direct Metal Laser Sintering (DMLS) uses a precise, high-wattage laser to micro-weld powdered metals and alloys such as Inconel, Aluminum, Stainless Steel, and Titanium. 3D printed parts will have a surface finish comparable to investment casting. By offering our post finishing services, printed parts can be de-burred, bead blast, or polished and ready for real world applications.

DMLS parts are strong, durable, and heat-resistant. DMLS eliminates time-consuming tooling, and creates complex geometries not possible with other metal manufacturing processes. DMLS produces functional metal parts with the same speed as other 3D printing services that only produce plastic parts.

Material Choices:

- Stainless Steel

- Aluminum

- Inconel

- Titanium

Fused Deposition Modeling (FDM)

FDM printing uses a plastic mono-filament that extrudes layer by layer to produce an exact 3D printed part. These are thermal plastics that fuse each layer by using extreme heat. FDM parts are strong and durable; they can be light-weight and are an excellent choice for functional prototyping.

Material Choices:

ABS:

- Available in Ivory, White, Black, Dark Grey, Red, Blue, Olive Green, Nectarine, & Florescent Yellow

- Ideal for affordable design concepts and quick studies

Nylon 12:

- Nylon 12 offers excellent chemical resistance and is perfect for friction surfaces

- Highly recommended for extreme performance in parts with thin wall surface features

Polycarbonate:

- Ideal for functional parts and has superior strength

Ultem:

- Ultem is a high-temperature, chemical-resistant thermoplastic, perfect for design testing in extreme conditions

- Ideal for autoclaving and food-safe applications

Stereolithography (SL)

Stereolithography (often called SLA or SL) rapidly builds components using a precise UV laser to cure and solidify thin layers of a photo-reactive resin. One of the most accurate 3D printing technologies, SL is ideal for concept models, form and fit studies, and investment casting patterns.

Stereolithography is not generally considered suitable for production applications because the photo-reactive resins used in the process do not remain stable under long exposure to UV light. However, SL is often used to make precise investment casting patterns to create end-use metal parts.

Material Choices:

Somos WaterShed:

- ABS-like performance with the clearest quality

- Good for flow analysis and prototype design

- Resistant to water and humidity

Somos NeXt:

- Tough SL resin that is ideal for low-volume manufacturing and functional prototypes

- Somos NeXt offers improved moisture resistance and greater thermal properties

Click on images to enlarge

CAD Services

Rely on HTS CAD Services for your most challenging applications.

HTS not only builds impressive, accurate 3D scale models, but we also have the knowledge and skills to create extremely accurate 3D CAD files.

After scanning your item with our state-of-the-art laser scanners HTS can convert the point cloud data to create an as-built 3D file or a geometrically correct 3D file, depending on your needs.

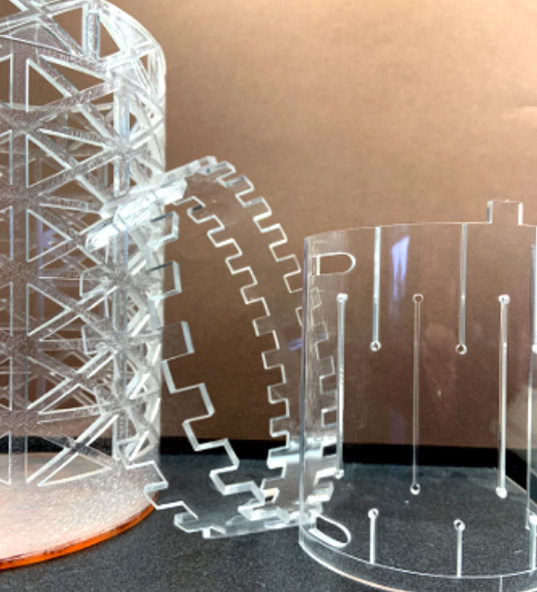

Laser Cutting Services

HTS offers state-of-the-art Laser Cutting Services to the general public. This process can quickly turn your drawings into laser-cut parts from some materials and greatly reduce the time normally needed to cut by hand or by pen plotter.

A wide range of materials can be cut and engraved using the laser cutter. HTS offers Laser Cutting Services for the following materials:

- Acrylic up to ½” thickness, flat or cylindrical

- Solid Wood – thickness varies by type

- Card stock/paper

- Some films and fabrics

- Glass and Granite can be etched but not cut

Need Laser Cutting?

HTS offers state-of-the-art Laser Cutting Services to the general public. This process can quickly turn your drawings into laser-cut parts from some materials and greatly reduce the time normally needed to cut by hand or by pen plotter.

Guidelines to follow before submitting your drawings:

PLEASE NOTE: Make sure there are no duplicate or overlapping lines (this will cause the laser to cut in the same place multiple times and will yield an undesirable result).

Laser Cutting Drawings Guidelines:

- Draw all parts with ordinary lines or polylines set to .001” width

- If using AutoCAD, make sure your drawing is set to the world coordinate system (WCS) and that all parts are drawn flat to the X, Y plane.

- Purge all unused layers and blocks

- Scale drawing to the desired size

- Space between cut lines should be no less than the material thickness. Contact us for exceptions.

- Group parts from the same material on sheets no larger than 32″ x 18″ for the Universal Laser and 36” x 24” for the Epilog Laser. Keep your parts at least 1/8” from the edge of the material

- Label each sheet with the material and thickness desired

- Pack parts with a spacing of no less than 1/8″

To Create Layers:

- If the layer is to have cut lines – name the layer “cut”

- If the layer is to have score lines – name the layer “score”

- More than one layer for each type of line can be created by adding a number designation: cut1, cut2, score1, score2, etc. This can be an effective way to control the order in which specific lines are processed.

- Please send files in DWG or DXF file formats. Contact us for optional file formats we can accept

Rapid Prototyping

Rapid Prototyping service is a technique used to quickly fabricate a scale model of a physical part or assembly using 3D CAD data. Construction of the part or assembly is typically done using 3D printing or “additive layer manufacturing” technology and this is where HTS can help.

Using our state-of-the-art 3D printers we can produce your test part very quickly. Then, with the prototype in hand, you can inspect & review it to determine if you are ready to go ahead and manufacture your product or refine it to fully fit your needs.

For additional questions on our Rapid Prototyping Service contact us at info@hts-3d.com

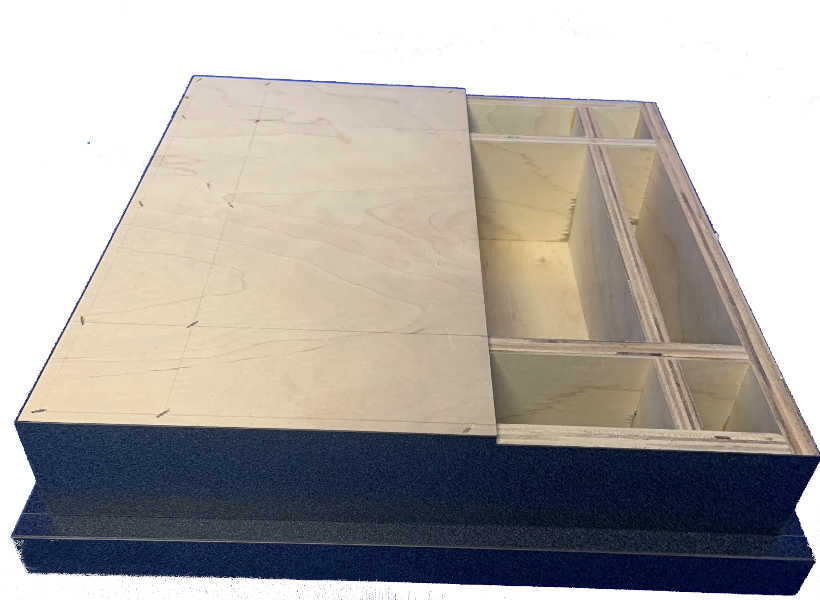

Model Bases/Pedestals

HTS model makers build custom-made bases and pedestals for each model using ¼” plywood with a torsion box technique, thus creating a strong foundation for your model.

The graphite nebula laminate adds durability to the base while giving it a professional, finished appearance.

Transit Containers & Model Covers

Packaging and transportation need be taken into account in order to ensure a safe and guaranteed delivery of your model. HTS can supply heavy duty transit cases, pelican cases and acrylic cases. The actual construction of your model, its size and its destination will determine the best choice for a transit case.

Model covers can be removable or hinged to open partially in order to demonstrate the functionality of the model. If your model is fragile or meant for long-term display an acrylic cover is recommended.

In addition to preserving its longevity, model covers protect against:

- Dust accumulation

- Accidental damage

- UV protection

- Moisture & humidity control

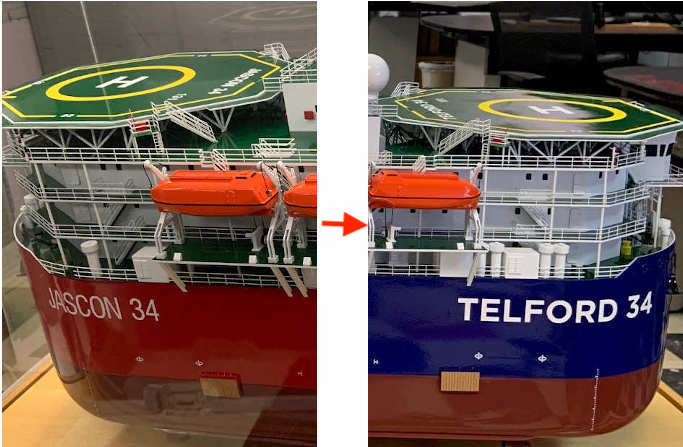

Model Painting / Rebranding

HTS model painting service uses only high-quality automotive paints and has a special process of preparing 3D-printed parts before paint so they have a smoother, more realistic surface finish.

We offer clear coat and matt finish choices along with color matching specific colors from samples and codes.

HTS can create special effects on finishes such as stone, wood, and other natural materials. We also offer special effect textures such as realistic acid etched, production-looking prototypes, and more.

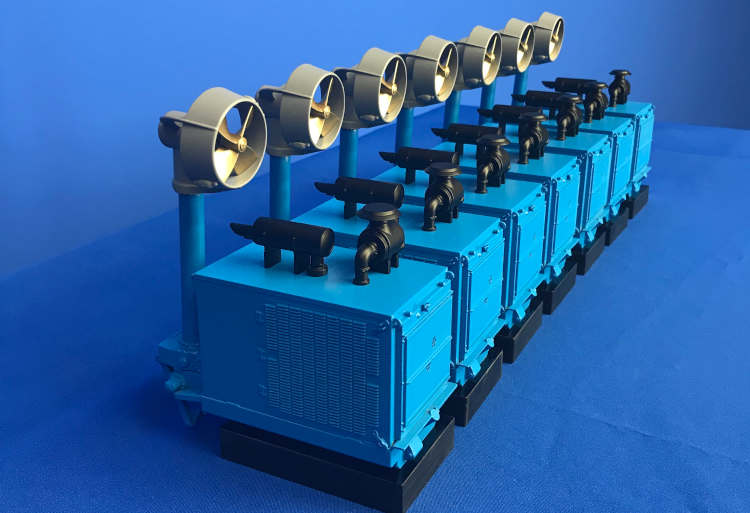

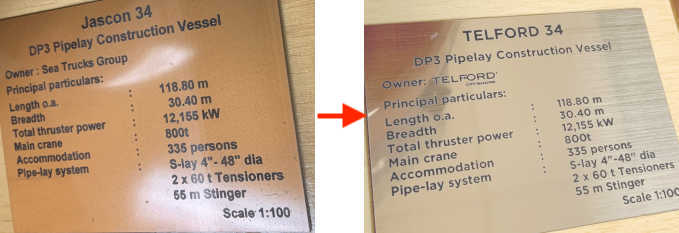

Images to the right show a recent rebranding project:

Jascon 34 marine vessel rebranded to Telford 34.

Red hull of the vessel was repainted in blue and the information plaque was updated.

3D Model Restoration

In addition to building professional custom-scale models, HTS offers comprehensive model restoration services and repairs. Our expert staff are adept at making your model look like new whether it is damaged or needs updating. Maybe a thorough professional cleaning is all that is required.

Let HTS modelers advise you on what is needed to restore your model to its former self.

Model Setup / Move

Depending on the model, just moving it to a different room can be a tricky operation. HTS Advanced Solutions staff can help, and prevent damage before it happens.

Do you have a trade show or exhibition coming up? There’s no one better to safely and efficiently transport the model, set it up, and make it ‘show ready’ than the experienced modelers at HTS. Then, at the end of the show, we’ll be there to move it back and re-install it to its permanent location. Leave it to the professionals who do this regularly.

Model Restoration / Repair

In addition to creating models, we repair, restore and revamp older models regardless of their origin. Models are easily damaged. Often their size (and sometimes their weight) makes it difficult to handle and even more difficult to move without damaging some part of it. HTS modelers deal with these situations every day.

If your model needs attention contact HTS to discuss your situation with our dedicated modeling team. We’ll advise you of the most cost-effective way of making your model look like new again. If possible we carry out repairs on-site, but if needed, we’ll transport the model to our fully equipped workshop to perform the work.

Model Updating

We update existing models regardless of their origin. If possible the work will be done at your location; however, depending on the model we may need to transfer it to our Houston facility, in which case, we take care of the logistics.

Be assured that HTS strives to minimize the cost to the client in all instances, while maintaining the professional end-result.

3D Model Cleaning

It is extremely difficult to keep a model dust-free. Compressed air can be used to remove any dust that may have settled on your model but please be mindful of using it around trees or grass fixtures in case they shed. Tiny replica items are not easily cleaned in the normal manner. This is where HTS Advanced Solutions can help.

A professional cleaning performed by our modeling team may be all that is needed to make it sparkle again. Our expert staff can do this at your location.